Keytech S.r.l. presso Interporto Marche - via Coppetella, 4 - ITALY - 60035 Jesi (AN)- P.Iva e C.F. 02387630425.

3D PRINTER FILAMENT

by KEYTECH s.r.l.

Description

of Present Situations

FFF (fused filament fabrication) is an additive manufacturing technology. A

fused filament fabrication tool deposits a filament of a material (such as

plastic, wax, or metal) on top or alongside the same material, making a

joint (by heat or adhesion).

Fused Filament Fabrication is equivalent to Fused Deposition Modeling.

However, the term fused deposition modeling and its abbreviation to FDM are

trademarked by Stratasys Inc. The term fused filament fabrication (FFF), was

coined by the members of the RepRap project to provide a phrase that would

be legally unconstrained in its use.

Objects printed with FFF are layered, so they have a grain like wood. Even

when printed with an infill rate of 100%, such objects are not quite as

strong (in some directions) as others. Tests show that printing the same

object in different orientations, with different infill patterns, can give

differences in strength of almost 2 to 1. An interlocking infill pattern

seems to give more strength. For more information, see the sources listed in

Further Reading.

From:

http://reprap.org/wiki/Fused_filament_fabrication

FDM uses the thermoplastics ABS, PLA, PA, WOOD, CLEAR POLYMERS, AND RUBBER,

major polymers used are PLA and ABS. For technical polymer with high

mechanical and thermal characteristic are used ABS, PA and few special PLA.

ABS and PA request hot bed and aren't easy to print like Standard PLA.

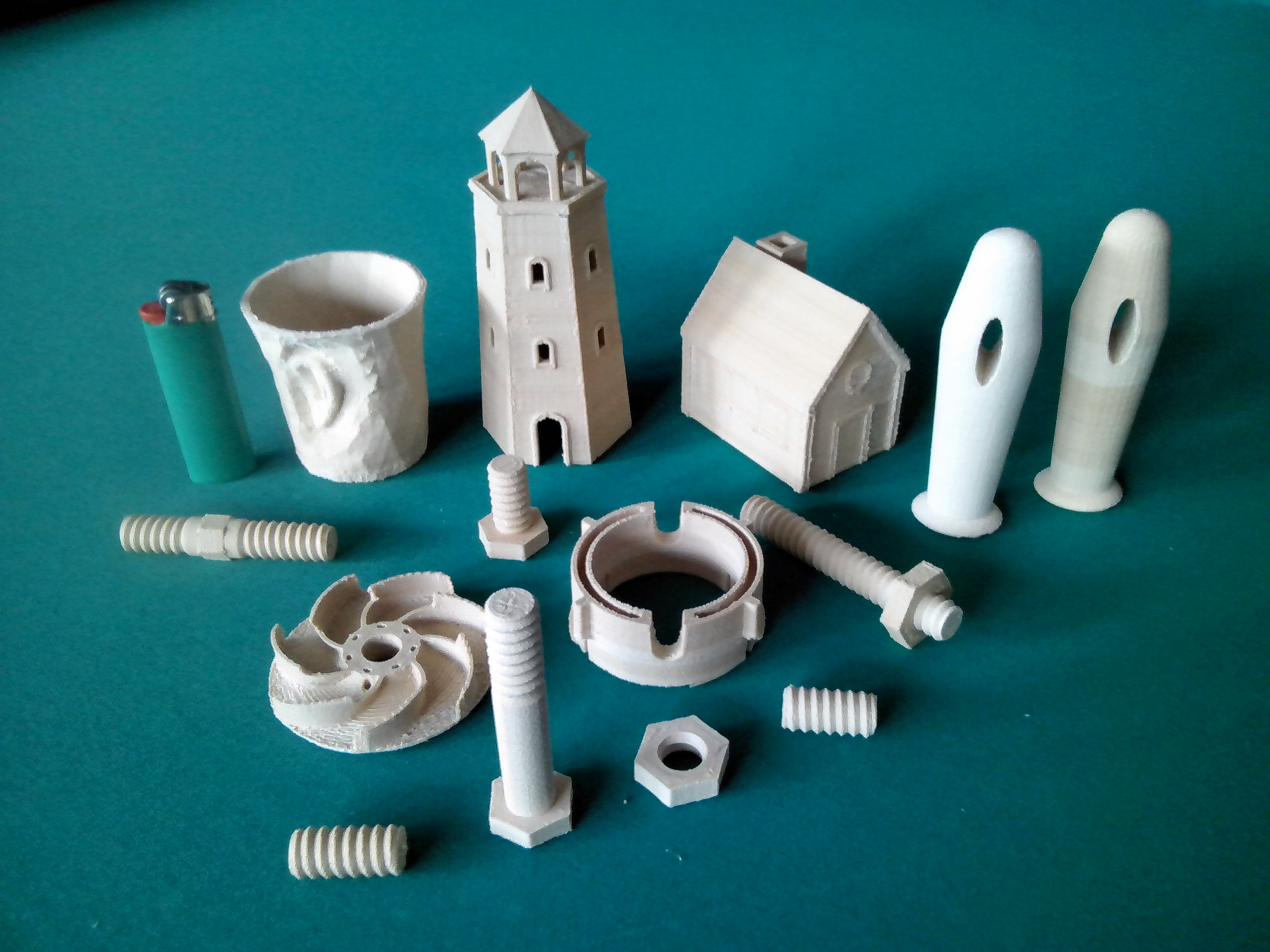

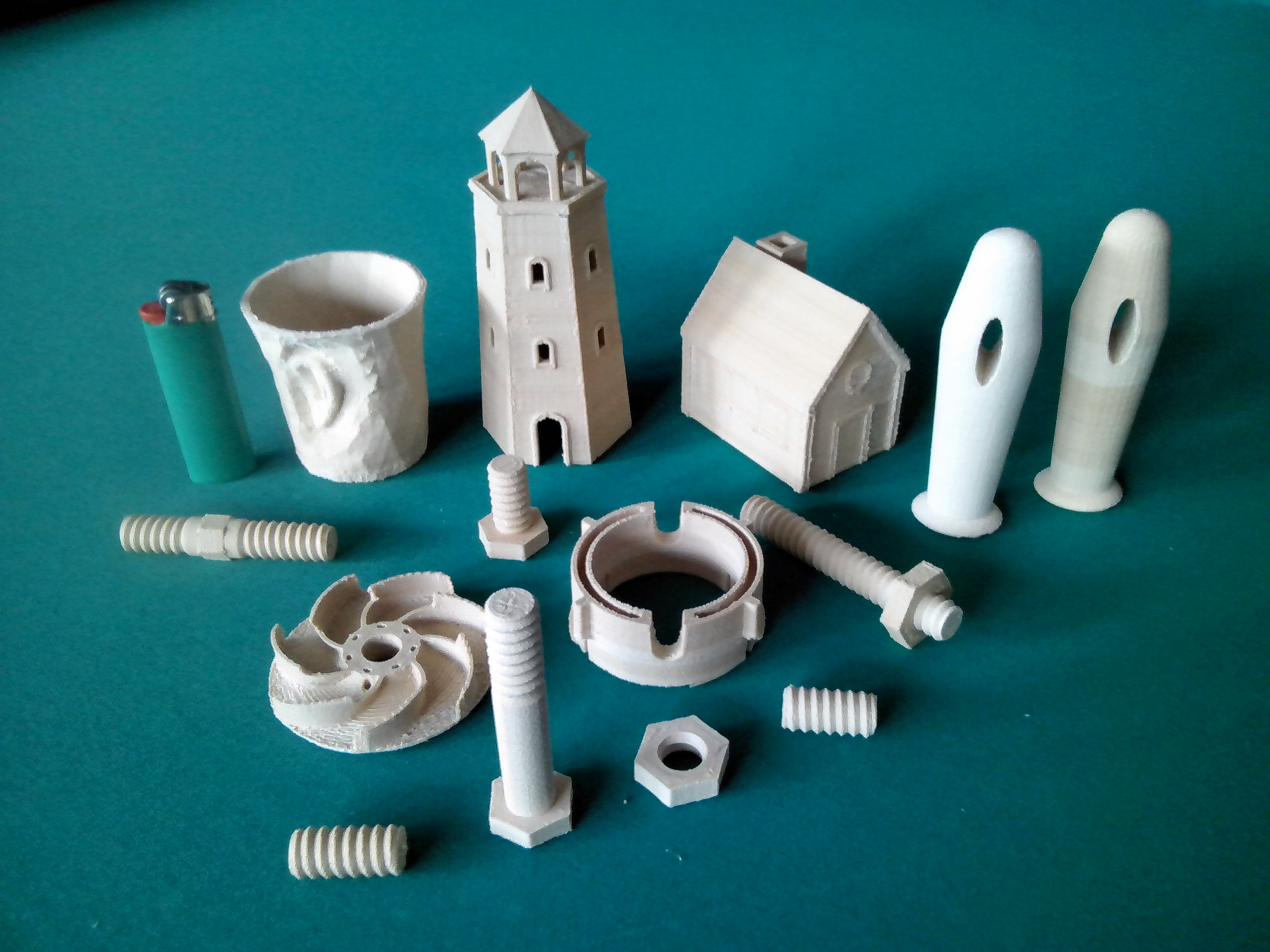

Description of KEYTECH 3D PRINTING FILAMENT

Keytech 3D Printing filaments are made with high special polymers, mostly

never use in 3D Printing till today.

These filament are made with high thermal and mechanical characteristics.

Particular attention are PolyKey PLA HS and PolyKey PLA HS NX who have a

similar thermal and mechanical characteristics of ABS and PA but are

possible and easy to print like PLA.

Others new polymers are PP (Polypropylene) Special Compound with high

thermal and mechanical characteristics better of ABS and PA, aren't

biopolymers and in meantime have also very low moisture absorption and will

be to print similar PLA.

On the next page you can see a best values and points of

Keytech 3D Printing

Filament.

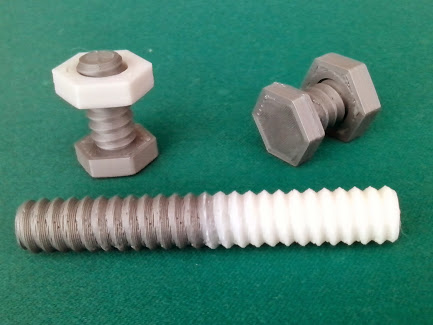

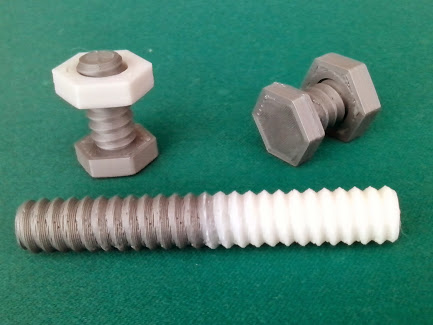

Threads for 3D Printers

- Standard

- Reinforced with mineral fillers

- Wood effect

- Aluminum effect

- Transparent

- Rubber

VISIT THE WEB SITE

Products: Arborbiokaps,

PolyPlus e

3D Stick & Filament